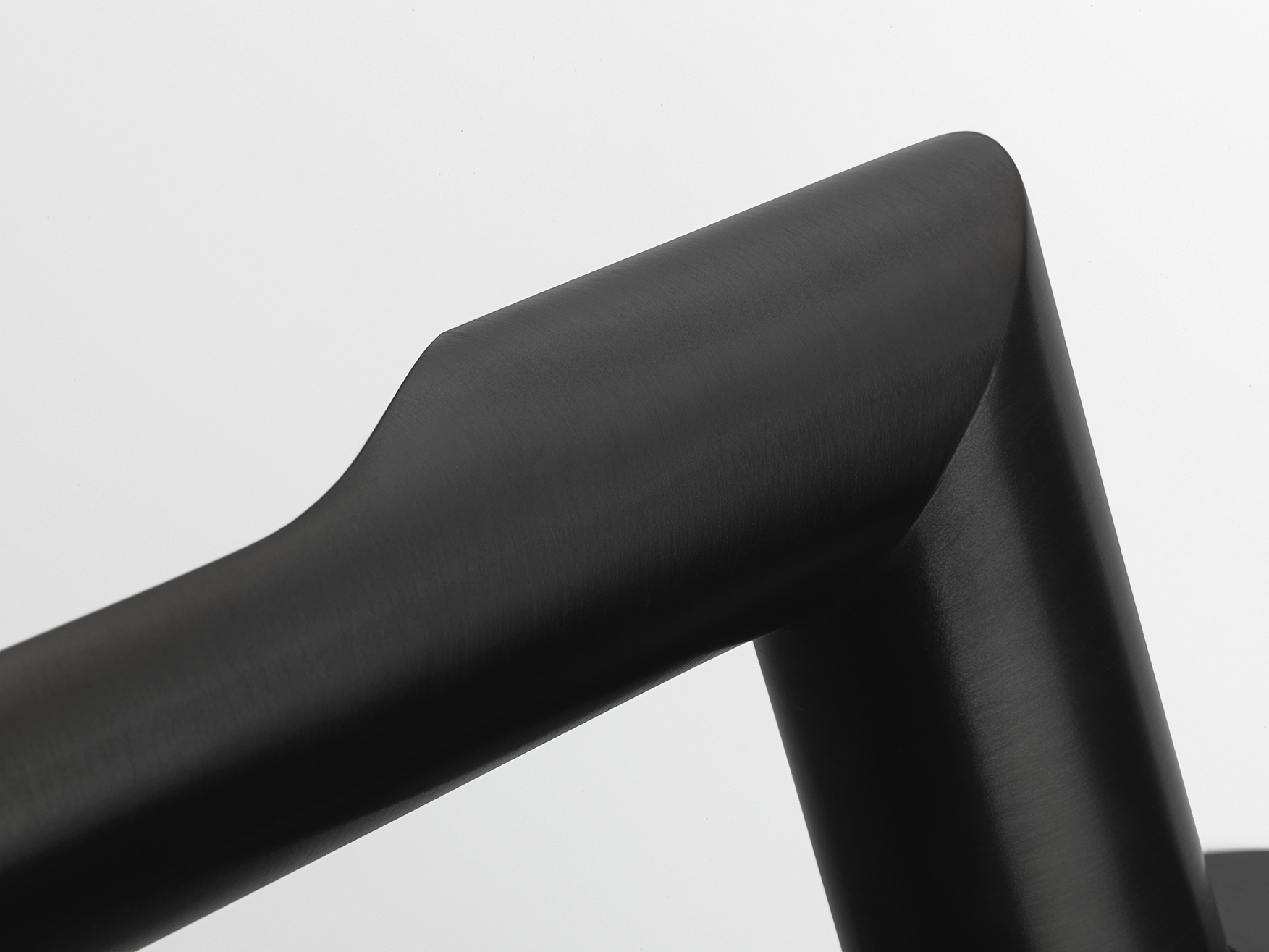

PVD door hardware

Enhacing your space with durability and Elegance

What is PVD door hardware

PVD stands for Physical Vapour Deposition. PVD door hardware refers to a specialized coating technique that involves the deposition of thin layers of metal alloys onto various surfaces, including architectural hardware like door handles, locks, hinges and other accessories. The PVD finish is ultra-thin but also extremely strong, which results in a top layer that is much harder than the substrate. This process enhances the durability, corrosion resistance, and overall aesthetics of the hardware, making it ideal for both residential and commercial applications.

The benefits of PVD door hardware – door handles, window handles, furniture fittings and other accessories:

• Unparalleled durability: due the extremely strong PVD top layer the door handles and other products are highly resistant to scratches, abrasions, and fading, ensuring that your door hardware maintains its original beauty for years to come. This means an increased quality of the products and a longer lifespan. Although, it must be said that no mechanisms, including lever handles are completely scratch-resistant.

• Weather, wind and corrosion Resistance: PVD-coated hardware is exceptionally resistant to corrosion, making it suitable for installation in various environments, including coastal areas with UV rays and salty air. Therefore a PVD coated door handle is also a good choice for front doors, garden doors or bathrooms.

• Easy Maintenance: The PVD finish protects the product against these influences and, although no product is completely maintenance-free, the coating ensures less maintenance. Together, this results in an extended life span.

• The PVD coating process is sustainable and eco-friendly: In addition to the durable quality of the end product, the PVD process is more environmentally friendly than alternative coating processes. No harmful gases or other substances are released and there is no waste. The process does not affect the recycling value of the stainless-steel base material. read more information about our approach at our sustainability page.

• Great designs: PVD coatings can be applied to a wide range of door hardware designs, allowing you to find the perfect style that complements your interior decor.

Exploring PVD door hardware options

1. PVD door handles

Elevate the appearance of your doors with PVD-coated handles, available in a variety of finishes and designs. Whether you prefer modern, minimalist styles or ornate, traditional motifs, PVD door handles offer both elegance and functionality.

2. PVD door accessories

Complete the look of your doors with a range of PVD-coated accessories, including hinges, pulls, knobs, stops, plates, latches, closers, and signage. These accessories not only serve practical purposes but also add a touch of sophistication to your interior or exterior design.

PVD colour options

The PVD (Physical Vapor Deposition) coating technique has long been utilized in various industries. Traditionally, the color options for PVD coatings were limited. However, in recent times, colored PVD coatings have gained significant popularity in the realms of architecture and interior design. With options like PVD satin black, PVD gunmetal, PVD satin gold, and PVD copper, architects and designers now have a wider range of aesthetic possibilities to explore. Additionally, PVD satin stainless steel provides the classic look of stainless steel with the added benefit of a hard top layer of PVD coating. Discover the diverse world of PVD color options available to you.

For a proper advice while choosing door hardware you can always consult with our professionals and experts to ensure to ensure the perfect fit for your door hardware.

Conclusion: With its exceptional durability, corrosion resistance, and versatile designs, PVD door hardware offers an unbeatable solution for elevating the functionality and style of your space. From handles and locks to accessories, each piece is meticulously crafted to provide long-lasting beauty and performance.

More information about (PVD) door hardware possibilities? Check these pages:

• FORMANI’s finish chart

• Request a colour box